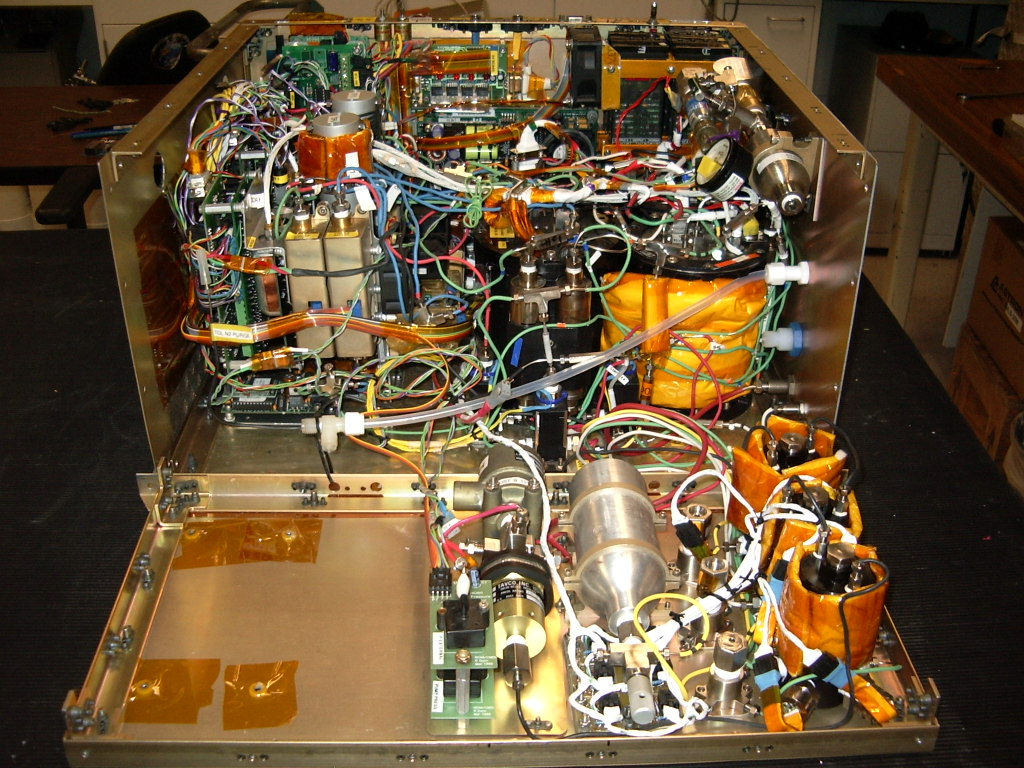

The 2-channel UCATS GC utilizes rapid gas chromatography to measure nitrous oxide (N2O) and sulfur hexafluoride (SF6) every 70 s, and hydrogen (H2), methane (CH4) and carbon monoxide (CO) every 140 s. Each channel is comprised of a 12-port valve for sample injection, a 1.5 cm3 sample loop, narrow bore (2.2 mm id) packed columns, and an electron capture detector (ECD). The N2O/SF6 and H2/CH4/CO measurements require doping of the ECDs with miniscule flows of carbon dioxide and nitrous oxide, respectively, from small, high-pressure cylinders inside the instrument. The GC carrier gas (N2) and calibration gas (whole air) are contained in aircraft-certified high-pressure cylinders external to the instrument box. A Teflon diaphragm pump, also external to the GC, flushes air samples through the GC for their subsequent analysis. For extended low-tropospheric flying, a small amount of dessicant (Mg(ClO4)2) is required to dry the sample air stream before it enters the GC. Calibration is performed in-flight every 560 s through the analysis of a standardized cylinder of dried whole air. Further calibrations are performed in the laboratory to characterize detector response functions over the full ranges of trace gas mixing ratios measured during flights. An on-board computer provides instrument control while continuously logging chromatographic and engineering data. Data are recorded on removable media (PCMCIA flash disk) during flight, then are archived off-line after landing. In the post-flight phase, chromatograms are processed into mixing ratio data with error estimates for each measurement.

Data Interval: every 70 s (N2O, SF6) or every 140 s (H2, CH4, CO)

Accuracy: ±1%

Precision: ±2-3%

(H2) ±0.2-0.5% (N2O)

±0.4-0.8%

(CH4) ±0.8-1.0% (SF6)

±3-5%

(CO)

UCATS

2-Channel GC